The Sound of Strymon: Sound Designer Pete Celi

Strymon co-founder Pete Celi is responsible for the sound design and DSP algorithm creation for all the Strymon pedals that use DSP. Recently I had the

Free US Shipping On Orders Over $49

Easy 30-Day Returns

Financing Available Through ![]()

Recently I had an opportunity to talk with Jorge Aguila – Senior Manufacturing Engineer at Strymon. Jorge is a man who wears many hats! In addition to overseeing manufacturing, Jorge is also in charge of quality assurance, shipping, and repairs. Check out the interview below to find out what I learned about Jorge and his team, and about manufacturing and quality assurance at Strymon.

What was the path that led you here to working at Strymon?

I was always intrigued by electronics as a kid, just taking things apart, although as a kid, I could never put things back together! When I got older I started taking some electronic classes and I really loved it. When I was 15 I enrolled myself in a VCR/TV repair class at an occupation center. I think that was the first time that I really dug electronics and thought, ok this is something that I want to do. So I took classes here and there until I felt confident and got into some small electronic companies. Over time I got stronger in electronics and more confident in what I was doing, and my troubleshooting skills got better. Eventually I had an opportunity to either go work for an audio company, or for an intelligent lighting company. I used to be a DJ and I used to do lighting, so [intelligent lighting] was appealing, but I decided to go the audio path, and I think I made a good decision because I love music. I’m not a guitar player—I can pick up a guitar and play a couple of chords, but I’ve always been passionate about music and I really love electronics, so, that’s kind of how I got into it.

What is your title here at Strymon?

Ah, I think it’s Manufacturing Guy maybe. [laughs] Titles really don’t exist here I guess, in the sense that there’s no job too big or too small. Being a small company you gotta be willing to do whatever it takes to get the job done.

So you oversee manufacturing, quality assurance, and shipping. How many in your team, including you?

There are four of us here. Five years ago when I first started it was just me!

[walking out onto the warehouse floor]

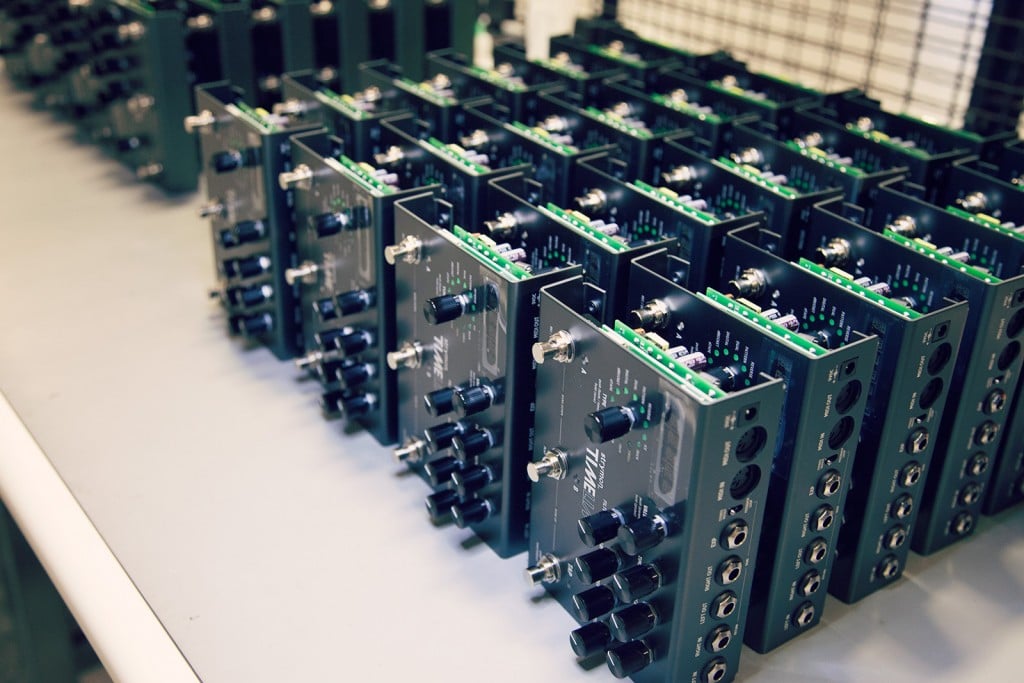

So we can start by introducing… that’s my brother John, this is Jose, we don’t have Victor here today, Victor’s on vacation. Victor takes care of all of the international, online, and dealer sales, but since he’s on vacation, John and Jose are filling in. We have a big order going to Japan here. This is our finished goods area. We have different sections for Europe, UK, Australia, US, and then over in this corner here we have Japan. Each country uses different power supplies and that’s basically the difference between a US, EU and UK pedal.

This looks like a pretty big warehouse for a fairly small crew.

It’s a big warehouse, so we all share a lot of responsibilities. All these guys have been hand picked. My brother John started out assisting me with whatever side work I needed. Now he’s in charge of ordering all the inventory, all the planning, and making sure that we don’t run out of parts, because without parts we can’t build. Some of these parts can have an eight to 16-week lead time, so John really has to plan ahead. If we run out of power supplies today, we’re down for months, so there’s a lot of responsibility in making sure that we don’t have too much, or too little. Just enough to keep us going.

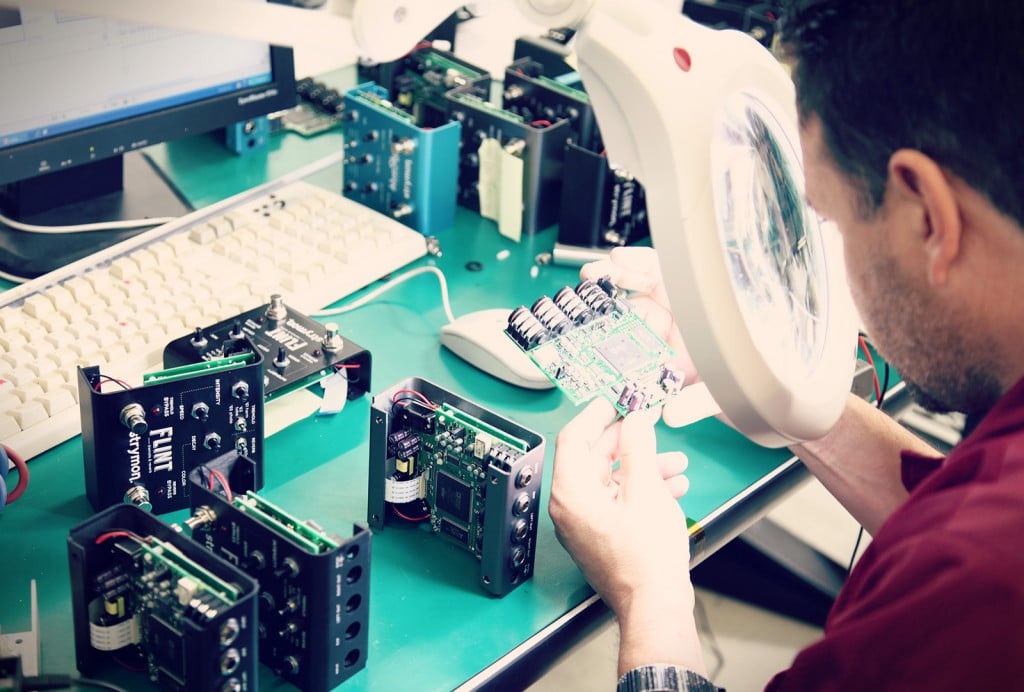

In addition to manufacturing and shipping, you are also responsible for quality assurance. Can you talk about that?

Being a small company, quality is number one. Every pedal that goes out is treated like it’s going to a rock star. Doesn’t matter who it goes to, it’s important to have a good pedal going out. We have about a half percent failure rate, return rate, which is very impressive. Many companies would be satisfied with a 5% return rate. But this year’s goal is to get that half a percent down to perhaps half of that. So it’s always a constant improvement. Besides having a great sounding pedal, if you open up that pedal and it looks beautiful inside, it’s all laid out correctly, that’s key. It’s very important. You only get one chance. It just takes one guy to have a bad experience and next thing you know ten guys are talking bad about your company and they haven’t even bought a pedal yet.

So first impressions are important, obviously.

The first thing a customer sees is the gift box, you know, when he gets it in the mail. He opens up the outer shipping box and then inside is the gift box. For me it’s very important that the customer opens up that box, and it’s beautiful. It doesn’t look beat up. It looks like it’s been treated properly. Then he opens the gift box, looks inside, and there’s a beautiful chassis. With no blemishes; the color is impressive. Obviously customers want to have a good sounding pedal, but if I release a pedal that has blemishes, or encoders are rubbing or pots are rubbing as you’re turning them, it doesn’t matter how good the pedal sounds, your first impression is “oh this is shitty.” It’s kind of like a car. I think the first thing you look at is the way it looks, the curves, the color. Once you like that then you sit in the car and you feel very comfortable in your seat and drive and feel how it handles. That’s the way I look at our pedals. How they sound and what they offer to the customer are very important, but the first impression is what they see.

Can you tell me a little about the process of coming out with a new pedal?

Sure. There’s what we call prototype building. During prototype building, we go through revisions, such as X zero through, say, X 4. After you get to X 4 then you do a final, or when we’re really confident we release a Rev A. We build a board from the ground up and do a lot of testing early on. Soon after we start to distribute units outside to beta testers. All the early stage testing is key to having a good product. You don’t want to go back and make changes to a product that’s already out in the field. Our goal is not to try to get as many products out the door as we can in a year. Our biggest focus here is to do it right. If a pedal is not ready, we don’t ship it. We wait. Even if it takes an extra three or four months. It’s not about the numbers, it’s about the quality of products you put out.

What kind of testing do you do to ensure durability and road-worthiness?

One thing we do is vibration testing. We don’t have a in-house vibration table, so we go to a lab that specializes in that. There’s also a drop test from about table height. Basically you just let it fall and make sure that it doesn’t get damaged in certain areas. Obviously if something is knocked hard enough out in the field, some damage can happen, but you want to eliminate as much as you can. Another thing we do as part of compliance when we certify our products is ESD (Electrical Static Discharge) testing. ESD can happen through the air or directly. You don’t want a unit that keeps resetting every time a customer rubs their tennis shoes on their carpet and then touches the chassis! So that’s tested in a lab, but that’s the sort of thing you try to eliminate in the design phase before you ever get to the lab.

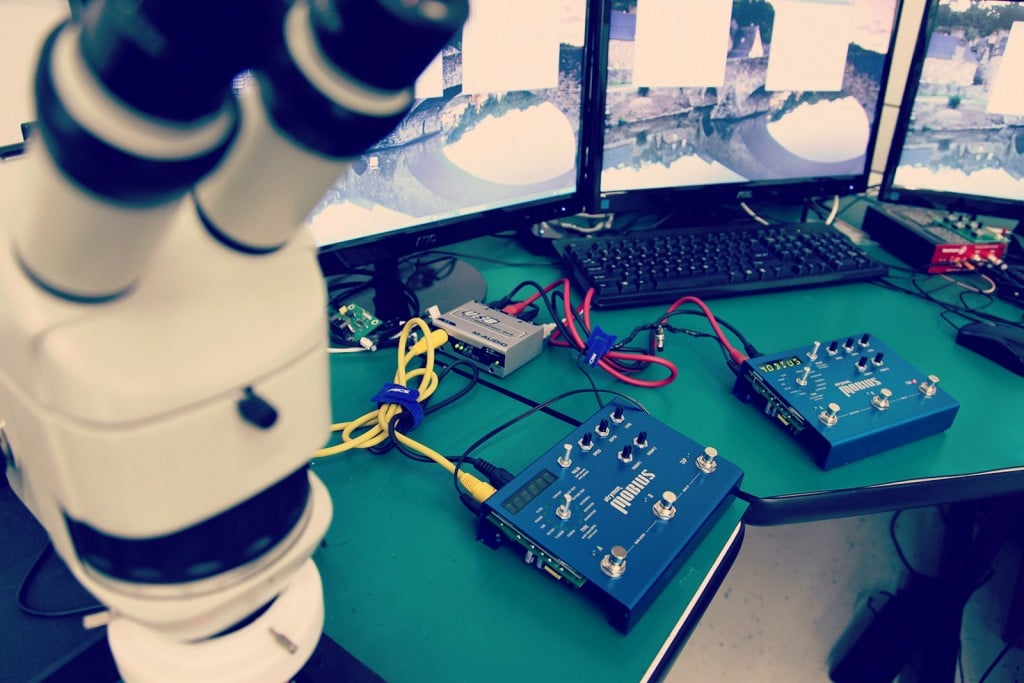

What kind of testing do you do once a pedal is in production?

We have an Audio Precision setup that we use for board level testing and final testing. It checks for signal to noise. It checks the wet signals, dry signals. We have the pedal go into test mode and we’re able to test all the functions on it. There are thousands of chances that things can go wrong. But we’ve got good enough systems, and we’re a small enough team that we can catch any manufacturing issue that comes up.

So all the pedals are made in the US, correct?

Producing in the US is big for us. Producing in China might save some money, but it’s not very effective, because what happens is engineering is on the phone or email really late because of the time difference, and then there’s the language translation issue, where maybe you don’t understand each other right away. Whereas here, if a problem pops up I can resolve the issue in perhaps half a day or maybe an hour, or even five to ten minutes, depending on the complexity of the problem. That way quality is controllable, whereas you produce in China and maybe now you have a boat that’s on its way with problems. And you don’t know it until you get it, and then you have a warehouse full of pedals that need to be reworked. So maybe manufacturing overseas is a good thing for some companies, but for us it’s worked out that manufacturing in the US is the way to go.

You also handle repairs here, right? Can you talk a little about that?

I think RMA’s are just as important as selling a pedal to a customer. We want to make sure that if we get the pedal in today, we repair it today. Occasionally if I’ve never seen the issue before I might test it and burn it in overnight, and maybe keep it for two days just to make sure, but for the most part we have a one day turnaround.

That’s amazing.

At the end of the day our customers are very important to us, not only when they buy a pedal but also when they need us to help them resolve their issues. When we sell a pedal we don’t consider our job done. It’s just the beginning of a new relationship for us. I feel that you can always turn a bad experience into a good experience.

Subscribe to our newsletter to be the first to hear about new Strymon products, artist features, and behind the scenes content!

Strymon co-founder Pete Celi is responsible for the sound design and DSP algorithm creation for all the Strymon pedals that use DSP. Recently I had the

It was 2005, and I was in eighth grade. I had just picked up the guitar and was taking lessons, so my friend Richard thought I’d

Gregg (our Senior Analog Guru and co-founder) contributed a helpful article about noise in guitar rigs to Premier Guitar for their freshly released September 2011